Our Commitment to High Quality Electrical Safety Test And Tagging

There are a lot of test and tag companies in New Zealand and diligence is required when choosing a test company (see Test & Tag Fraud), and not all will:

a) Visually Inspect all your equipment

b) Carry out all the correct and necessary electrical tests according to the Standard AS/NZS3760:2010

c) Put a ‘PASS’ label on the equipment only when a) and b) above have been completed and the equipment passed

d) Use labels that are very tough and rugged and that comply with the requirements of all Standards

e) Save actual test results in ‘real’ time to a secure memory on the tester

f) Provide from e) above reports with values as well as PASS and FAIL results

h) Put information on the tags for easy audit by the customer

i) Give real value for money with very competitively priced testing

Patreviews will and also give you much more including:

Confidence that the testing has actually been carried out

The quickest form of testing is to do a visual test only and a majority of faults can be found this way, but this does not tell you if the appliance is necessarily safe or meets the Standard. The remaining faults are often earth faults and these cannot be found other than by completing an earth and insulation test where required. If companies use testers without internal memories and use a separate manual entry of data, there is no way to know for sure if full testing of the appliance took place, or if only a visual test was performed. With our system there is no manual entry of data into a spreadsheet – the results are taken from the testers’ memory and downloaded into a computer program. If we have not done the full testing on a piece of equipment then there will not be a result for it.

Surety that your equipment is safe to use

The idea of testing is to know that the equipment is safe – not just to show you have complied with health and safety requirements to take ‘all practicable steps’ to provide a safe environment. Patreviews believes that safety should be a priority so when an appliance we are testing fails we fit a ‘Danger’ tag together with a label clearly noting the fault. We will also remove plugs from failed appliances if requested.

Confidence that the testing has been completed correctly and safely

Our testing technicians are fully trained and qualified. A person does not need to be electrically qualified and registered to test and tag equipment they only need to be ‘competent’. At Patreviews we strive to ensure that all our technicians are fully trained and capable of carrying out testing to a high degree of competency at all times. All testing technicians are vetted with Police and CAA Clearances and have Site Safe Passports. Patreviews has a proven health & safety record with Impact and Greenstone, and holds Spotless Facility Services Accreditation.

Detailed reports of testing in digital and printed formats

As part of our service customers receive a complete range of printed and digital reports of the testing created from information which is stored on the tester and then downloaded for accuracy and reliability. This includes a Summary of Tests, Fails Reports, and Testing Reports by Site & Location which show all the individual tests carried out on appliances together with the test values and ratings.

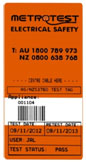

Quality and fully compliant tags (labels) which meet the Standard and last the specified time

Our printed tags contain all the details that are needed to comply with the Standard AS/NZS 3760:2010 2.4.2.1

‘The tag shall be durable, legible, non-reusable, non-metallic and may be colour coded to identify the period in which the test was performed, and shall include all of the following information as a minimum:

(a) The name of the person or company who performed the test;

(b) The test or inspection date, and shall include a retest date.’

Not all testing tags are made equal. They may even all look the same, but some will be made of a low quality material (sometimes even paper) which results in them deteriorating quickly or falling off. Our tags are constructed from a tough synthetic material with a bonded laminate overlay and a good quality adhesive to make sure they stay where they are put.

All portable hand held equipment that falls into the category requiring testing under AS/NZ3760 is inspected, tested and tagged in accordance with the requirements of this Standard. The 2010 version of AS/NZS3760 is used and the requirements of AS/NZS3760 are adhered to as a minimum requirement. No items are passed as technically safe if considered otherwise and the definition of appliance and the category of appliance type is taken from AS/NZS3760.

However, for single phase appliances where the conducting a 230V leakage test is the only effective means to fully test the appliance, then this test is carried out. When this 230V leakage test is performed the requirements of AS/NZS3760 version 2010 is used to ensure that the appliance under test is safe.

AS/NZS3760 is the minimum standard to which testing is carried out and we reserve the right to test above the requirements of this Standard. Read more

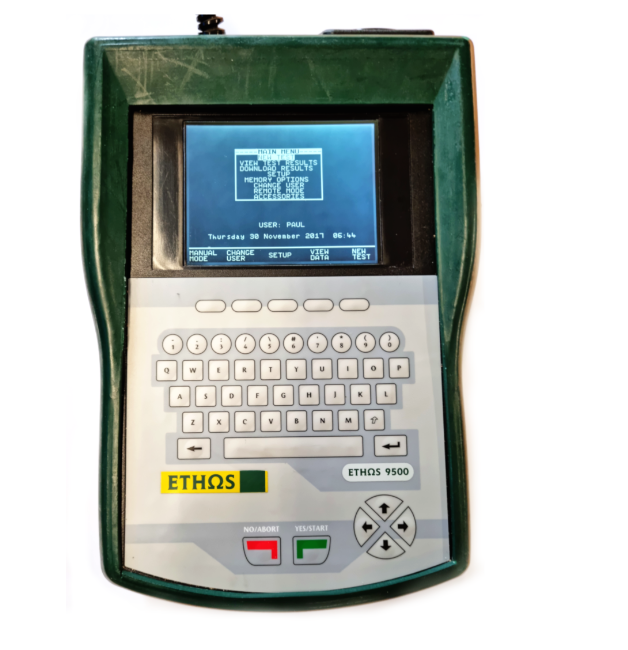

Instrumentation

Tests are performed using SupaPATsTM – advanced portable appliance testers that store results and print bar-coded tough vinyl labels or tags. Most test equipment used by Patreviews is less than 12 months old, is well maintained and fully calibrated within the last 6 months thus allowing full compliance with AS/NZS3760.

Testing Records

Results of all tests carried out are stored in an extensive database which is available to you on CD or in any format that you require. Details of records will include:

- Asset number (ie unique number applied by Patreviews)

- Site

- Location (where possible)

- Description of appliance

- Date tested

- Retest date

- Type of tests carried out

- Test results

Labels

Heavy duty thermal transfer printed test labels are supplied free of charge and are available in a range of colours so that an appropriate one can be selected. Where the tag is to go on an appliance or lead that may be subject to use in a harsh environment, an additional protective seal is applied. The bar code on each tag contains a unique identity number for the appliance or lead.

Heavy duty thermal transfer printed test labels are supplied free of charge and are available in a range of colours so that an appropriate one can be selected. Where the tag is to go on an appliance or lead that may be subject to use in a harsh environment, an additional protective seal is applied. The bar code on each tag contains a unique identity number for the appliance or lead.

Mechanical Condition of Appliances

If during electrical inspections and testing it becomes apparent that there is some other hazard/danger (non- electrical) associated with the equipment which could result in a problem to the operator of the equipment or to any other person, then we advise accordingly.

Repairs

Our company offers an independent test and tag service and to remain independent and to avoid any perceived conflict of interest we DO NOT undertake repairs to failed equipment unless this is required by the client.

Further Notes:

- Patreviews holds full Public Liability Insurance of $10 Million

- Patreviews have a proven health & safety record with full accreditation with Impact, Greenstone & Spotless Facility Services

- The testing conducted is ‘In Service Testing’ and not ‘Type Testing’

- Appliances that fail the testing have a ‘Danger’ tag fitted together with a large label detailing faults and plugs are removed if requested

- If dismantling of an appliances is necessary to enable testing, additional charges may apply as AS/NZS3760 does not extend to dismantling for testing purposes and permission would be sought and a price given in advance

- Access to equipment needs to be unrestricted. Any barriers or obstacles need to be moved and keys made available.

- If access is restricted, then help would be required to enable testing to proceed

- No hidden extra charges

- All testing Technicians are vetted with Police, Defence and CAA Clearances and have Site Safe Passports